Laboratory of Mechanical Properties

Department of mechanical testing

The testing machine AIMA-5-2. Tests on creep and creep strength in air at temperatures up to 1000°C and loads up to 30 kN.

The testing machine AIMA-5-2. Tests on creep and creep strength in air at temperatures up to 1000°C and loads up to 30 kN.

Prolonged annealing in air at temperatures up to 1000°C (oven PM-1.0-7) and 1200°C (oven PCL-1.2-12).

Prolonged annealing in air at temperatures up to 1000°C (oven PM-1.0-7) and 1200°C (oven PCL-1.2-12).

Equipment NANOTEST. Tests on the air on the microhardness, wear resistance, breakdown cycling blow.

Equipment NANOTEST. Tests on the air on the microhardness, wear resistance, breakdown cycling blow.

The determination of the resistance to corrosion stress cracking in aggressive environments.

The determination of the resistance to corrosion stress cracking in aggressive environments.

Determination of strength and plasticity characteristics during short-term testing of materials in tension, compression and bending in the temperature range from -100 to +1000°C and load up to 100 kN (equipment Instron-1251, Instron-5982 and FP-100/1).

Determination of strength and plasticity characteristics during short-term testing of materials in tension, compression and bending in the temperature range from -100 to +1000°C and load up to 100 kN (equipment Instron-1251, Instron-5982 and FP-100/1).

Investigation equipment Instron-5982

Investigation equipment FP-100/1

Determination of impact strength at temperatures from -196 to +600°C (impacting mechanism PSV-30).

Determination of impact strength at temperatures from -196 to +600°C (impacting mechanism PSV-30).

Determination of hardness at room temperature by the methods of Rockwell, Brinell, Vickers (hardness- measuring instrument TP-7R-1, TP-2, TP 2140, TK-2M, SH-2M).

Determination of hardness at room temperature by the methods of Rockwell, Brinell, Vickers (hardness- measuring instrument TP-7R-1, TP-2, TP 2140, TK-2M, SH-2M).

IMP UB RAS, Vladimir A. Zavalishin, e-mail: zavali@imp.uran.ru, tel. (343)3783868.

Mössbauer spectroscopy group

Mössbauer spectrometer MS-1101 with a proportional counter.

It is used to study the hyperfine structure of ferrous alloys. As a source of ionizing radiation is used 57Co in the matrix of chromium or rhodium. The spectrometer is equipped with consoles for measurements in a wide temperature range from -196 to 300°C.

Mössbauer spectrometer MS-1101 with a resonant detector.

It allows mössbauer measurements of iron samples irradiated with residual activity. As a source of ionizing radiation is used 57Co in the chromium matrix. A feature of this spectrometer is that for the registration of past g-quantum resonant detector is used, allowing to discriminate parasitic g-rays emitted due to radioactive decay of the material subjected to irradiation in a nuclear reactor. Perhaps the use of the cryostat for measurements in the temperature range from -196°C to room temperature.

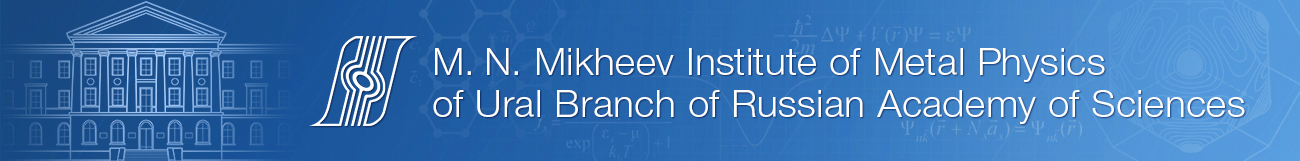

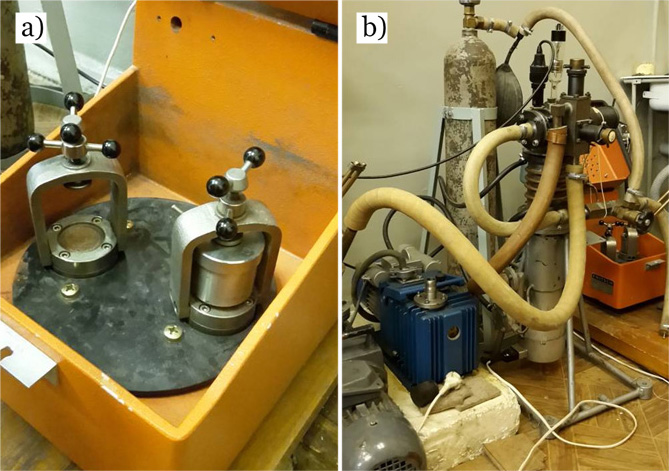

Planetary ball mill Pulverizette-7 (a) and the general plan of equipment base (b).

It allows automatic synthesis of powder materials in the laboratory. Regulation of the drum rotation speed up to 800 rpm. To reduce unwanted mass transfer of the material of balls and glasses in the amount of the treated mixture using a headset of high strength steel SHKH15. The design of the mill allows the grinding as in a normal atmosphere and in vacuum or controlled environment. So, to avoid oxidation of the powder mixtures milled in an inert atmosphere of argon.

Head of scientific group – Dr., Main Researcher Valery A. Shabashov.