Laboratory of Semiconductors and Semimetals

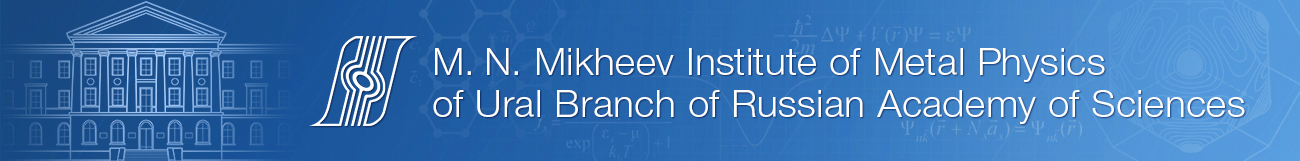

Setup for measurements of thermoelectric properties under pressure up to 30 GPa at room temperature (with synthetic diamond anvils)

Setup for measurements of thermoelectric properties under pressure up to 30 GPa at room temperature (with synthetic diamond anvils)

Details of experiments with using of this apparatus:

- smooth generation of applied force (quasi-hydrostatic pressure) and automatic recording of the electrical and mechanical parameters of the sample

- measurement of thermoelectric power in two regimes:

- at a fixed pressure and simultaneous changing of temperature gradient

- at a fixed temperature gradient and gradual changing of applied pressure

- measurements performed at a microscopic samples having a discoid form with a diameter of about 200 microns and thick of about 30 microns

- Chamber with the modified Bridgman anvils from synthetic diamonds with working diameters of ~ 600 microns are used to generate pressure up to 30 GPa

- as a gasket and a pressure-transmitting medium is a container made of limestone (soft mineral based on CaCO3)

- error in determining of values of thermoelectric power at high pressures, does not exceed 5%

- pressure values are evaluated on the calibration curve based on well-known and clearly observable transitions in crystals under pressure with an accuracy of about 10%

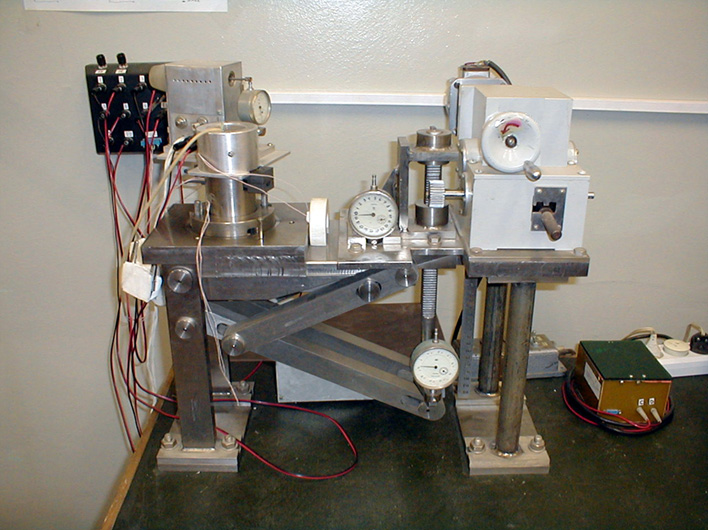

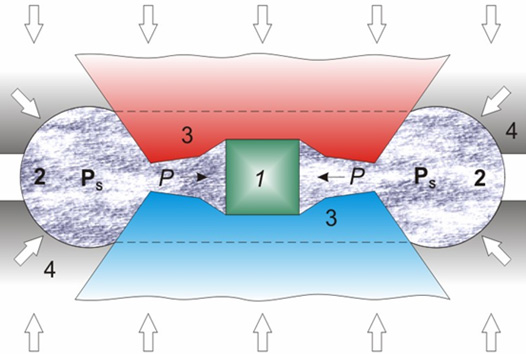

The sample in the high-pressure chamber:

- Sample

- Gasket from lithographic stone serving as the pressure transmitting medium

- The insertions of synthetic diamonds (anvils)

- Supporting matrixes form hard alloys

Annular thickening in the gasket 2 produces back pressure Ps (up to 10 GPa) at the edges of the anvils. High hydrostatic pressure P generated in the central part of the chamber.

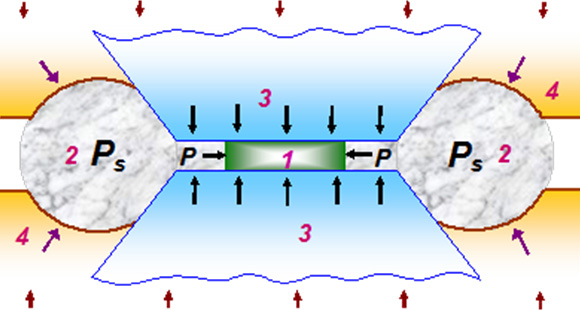

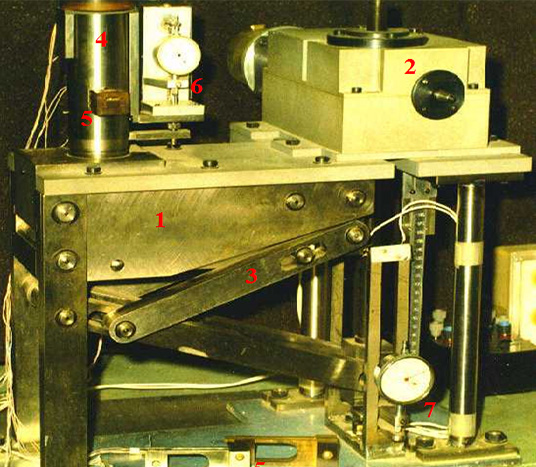

Device for measurements of thermoelectric properties under pressure up to 10 GPa at room temperature (chamber with hard-alloyed anvils)

Device for measurements of thermoelectric properties under pressure up to 10 GPa at room temperature (chamber with hard-alloyed anvils)

Details of experiments with using of this apparatus:

- smooth generation of applied force (quasi-hydrostatic pressure) and automatic recording of the electrical and mechanical parameters of the sample

- measurement of thermoelectric power in two regimes:

- at a fixed pressure and simultaneous changing of temperature gradient

- at a fixed temperature gradient and gradual changing of applied pressure

- measurements performed at a microscopic samples having a discoid form with a diameter of about 200 microns and thick of about 30 microns

- Toroidal-type chamber with a hemispherical concave anvils with a working diameter of 1 mm made of solid carbide-tungsten alloy used to generate pressure up to 10 GPa

- as a gasket and a pressure-transmitting medium is a container made of limestone (soft mineral based on CaCO3)

- error in determining of values of thermoelectric power at high pressures, does not exceed 5%

- pressure values are evaluated on the calibration curve based on well-known and clearly observable transitions under pressure with an accuracy of about 10%

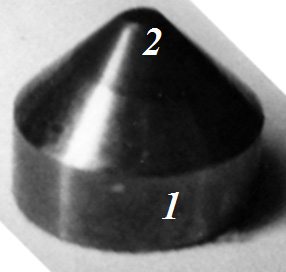

The sample in the high-pressure chamber:

- Sample

- Gasket from lithographic stone serving as the pressure transmitting medium

- The insertions from solid carbide-tungsten alloy (anvils)

- Supporting matrixes form hard alloys

Annular thickening in the gasket 2 produces back pressure Ps (up to 10 GPa) at the edges of the anvils. High quasihydrostatic pressure P generated in the central part of the chamber.